NEWS

DuPont Chemical Introduces New Fluorescent Film Material Technology

DuPont Chemical Introduces New Fluorescent Film Material Technology

Release time:

2019-12-27 14:41

Source:

The current increase in the application of smart lighting, automotive lighting, displays and backlights has driven the development of the LED demand market. The size of the LED packaging market has grown rapidly in the past few years. In order to maintain this amazing growth rate, high-power LEDs must not only provide higher reliability, lower power consumption, thinner and thinner dimensions, but also achieve higher Contrast and color accuracy to cope with a variety of ambient light conditions, so key materials will affect the luminous efficiency of the LED packaging process and the thin design direction of components.

The LED packaging industry utilizes semiconductor technology-Chip scale package. CSP LEDs have emerged as the times require. They are only one-tenth the size of traditional packages. They have a small size, low thermal resistance, wide viewing angle, and can eliminate the need for brackets. And wire bonding process and integrated packaging production, reducing the price difference with traditional packaging. Its characteristics are small size and wide viewing angle, reducing the number of components, which is promoting the application in the field of backlight modules, including mobile phones, computer screens, and televisions. With the thinner and more versatile smartphones, more modules must be integrated , Such as a small size, high power flash (CSP Flash) is also one of the components; of course, we must not mention that in the automotive headlight market, can achieve high brightness, light consistency characteristics requirements.

Forecast of Wafer-Level Package LED Production from 2012 to 2021

https://kknews.cc/zh-tw/tech/engqzqr.html

Aiming at the specificity of CSP LED package, the traditional potting process is used to spot the fluorescent glue on the surface of the chip. Due to the particle size of the fluorescent powder, the uniform dispersion of the fluorescent powder, the bonding strength of the chip and the interface stress directly affect the color temperature. Drop rate and reliability; To this end, DuPont Chemicals has introduced a new optical grade packaging material-a fluorescent packaging film made of curable hot-melt silicone or called B-Stage fluorescent film. After mixing this glue with fluorescent powder, it will show a semi-solid state after being cured by the film making machine. It has a slight stickiness, that is, a fluorescent glue film. At this time, place the glue film on the LED module. When the temperature is between 80 ° C and 140 ° C, the hot pressing process is performed, the glue will melt and completely cover the wafer, and then heated to 150 ° C, the glue can be completely reacted, and it is an irreversible reaction. This innovative type of material can simplify the production process, reduce costs, and better design flexibility. At the same time, it can reduce the precipitation and uniformity of phosphor distribution, which can help improve yield and better CSP LED packaging process.

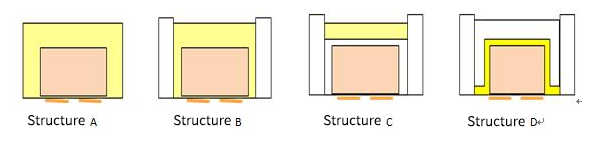

CSP LED package structure diagram

Structure A: The fluorescent film directly covers the wafer to form a 5-sided light emitting CSP LED.

Structure B: A fluorescent film is used to cover the wafer, and a white high-reflection silica gel is used as a vertical surface to form a single-sided light-emitting structure.

Structure C: The white high-reflection silicone vertical surface is formed first, and then the fluorescent film is hot-pressed to form, which is also a single-sided hair structure.

Structure D: After forming a 50 ~ 70um ultra-thin fluorescent layer on the wafer by coating with fluorescent glue, the white high-silica gel is used as the vertical surface, and then the transparent silica gel is encapsulated and protected in the reflection cup.

The current LED industry's innovation towards miniaturization and refinement development will be a new challenge for the LED market. Provide a variety of application materials for the LED packaging process; in the era of rapid changes in technology and technology, adhere to the innovative service-oriented, provide the best Total Solutions to help customers in the field of LED applications and layout.

Tel:0769-8155-9588 E-mail:dg.service@doit-technical.com.cn Address: Room 601, 6th Floor, 36 Fuxing Road, Chang 'an Town, Dongguan City, Guangdong Province

Tel:0769-8155-9588

E-mail:dg.service@doit-technical.com.cn

Address: Room 601, 6th Floor, 36 Fuxing Road, Chang 'an Town, Dongguan City, Guangdong Province